OLED panels have various advantages over conventional displays with LED backlighting. They offer true black tones because they light up automatically and can therefore also be completely "off". This leads to improved colors and a very high contrast. Due to these properties, OLED displays are the first choice for smartphones, televisions or even (preview) monitors in professional video production.

However, the best possible image quality currently available also has a not insignificant drawback: if OLED displays show an unchanged image, such as a static desktop or a menu bar of a program that has been in use for a long time, the individual pixels can "burn in". If this happens, they can no longer completely change their display, but the burnt-in pixels remain as a pattern and constantly overlay the image from this point onwards.

Although the undesirable burn-in behavior of OLED displays has improved noticeably over the last decade, the burn-in problem has never completely disappeared. Which is why some users continue to avoid OLED technology altogether.

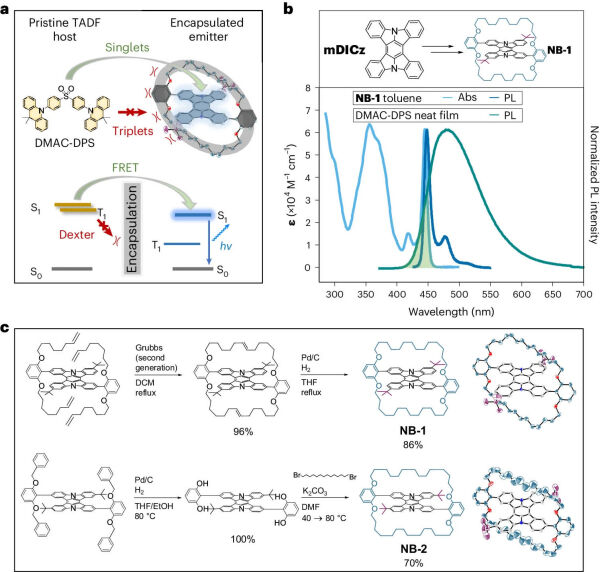

However, researchers at the University of Cambridge now claim to have found a method with which the burn-in effect in OLED panels can be fundamentally avoided. In a recently published study, the researchers claimed that "covalent encapsulation of the emitters for ultra-narrowband blue light in insulating alkylene ribbons could significantly reduce burn-in and even simplify the manufacturing process of OLED displays."

While current OLED panels use multiple layers of special materials to reduce the burn-in effect, the new technology could effectively eliminate all additional layers by simply covering the blue light-emitting diodes with insulating alkylene tapes. This would reduce the complexity of the manufacturing process and consequently lower production costs.